Research Experiences & Projects

Research

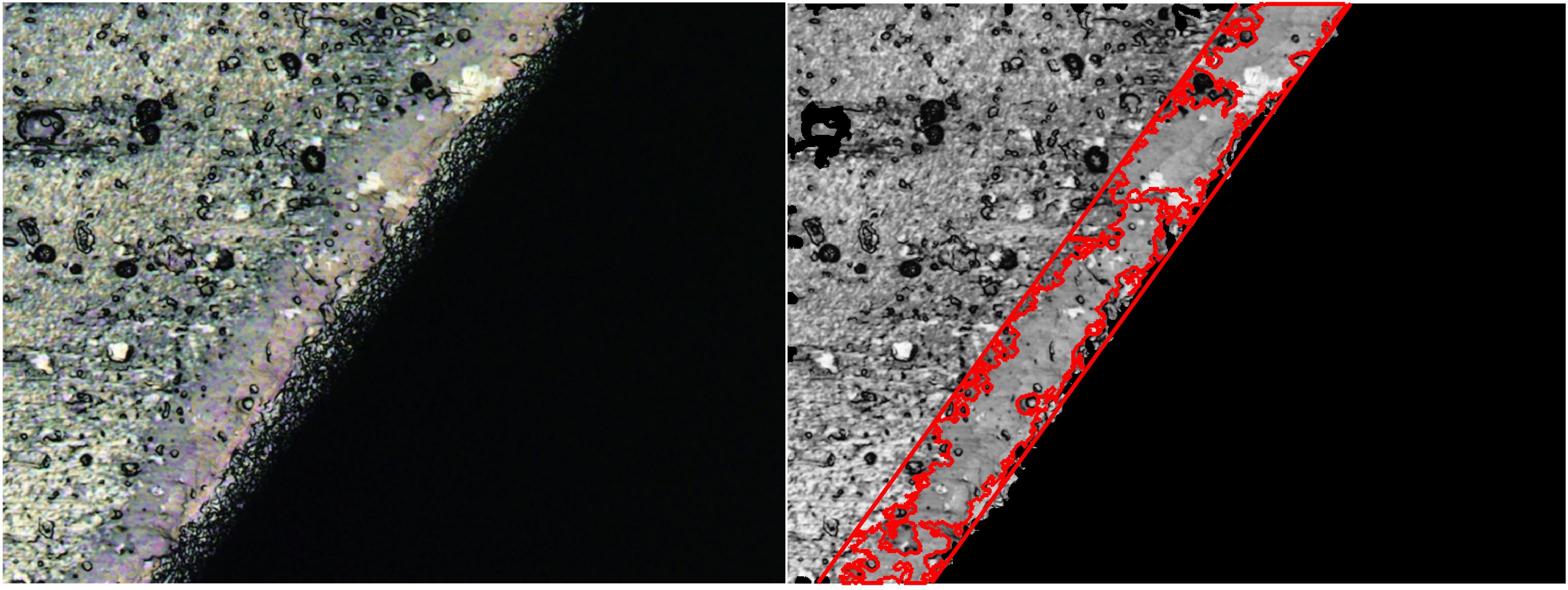

- Wear Band Segmentation

- RA, Supervised by Prof. Ming Chen & Prof. Qinglong An

- Shanghai, China; 12/2020 - 03/2021

- Utilized CCD camera to shoot the flank face of the cutting tool, determined the wear boundaries, and got the area and the perimeter of the wear region

- Extracted region of interest through image preprocessing, threshold segmentation, regiongrowing, and edge detection based on the Canny operator

- Code

- Tool Performance Quick Evaluation System: Cutting parameters Analysis and Tool Life Prediction

- RA, Supervised by Prof. Ming Chen & Prof. Qinglong An

- Shanghai, China; 09/2020 - 03/2021

- Established a tool performance Quick Evaluation System(TPQES), including cutting parameters analysis and tool life prediction, contributing to a 60% reduction in evaluation time and 32% increase in tool life for metal shell processing of 3C products

- Set-up of machine, tool and fixture in virtual machining module, got the cutting parameters along the cutting path, and obtained the the most representative processing parameters

- Conducted cutting experiment with the above processing parameters, combined the measured wear amount with TPQES to derive the tool wear curve

- More details about TPQES

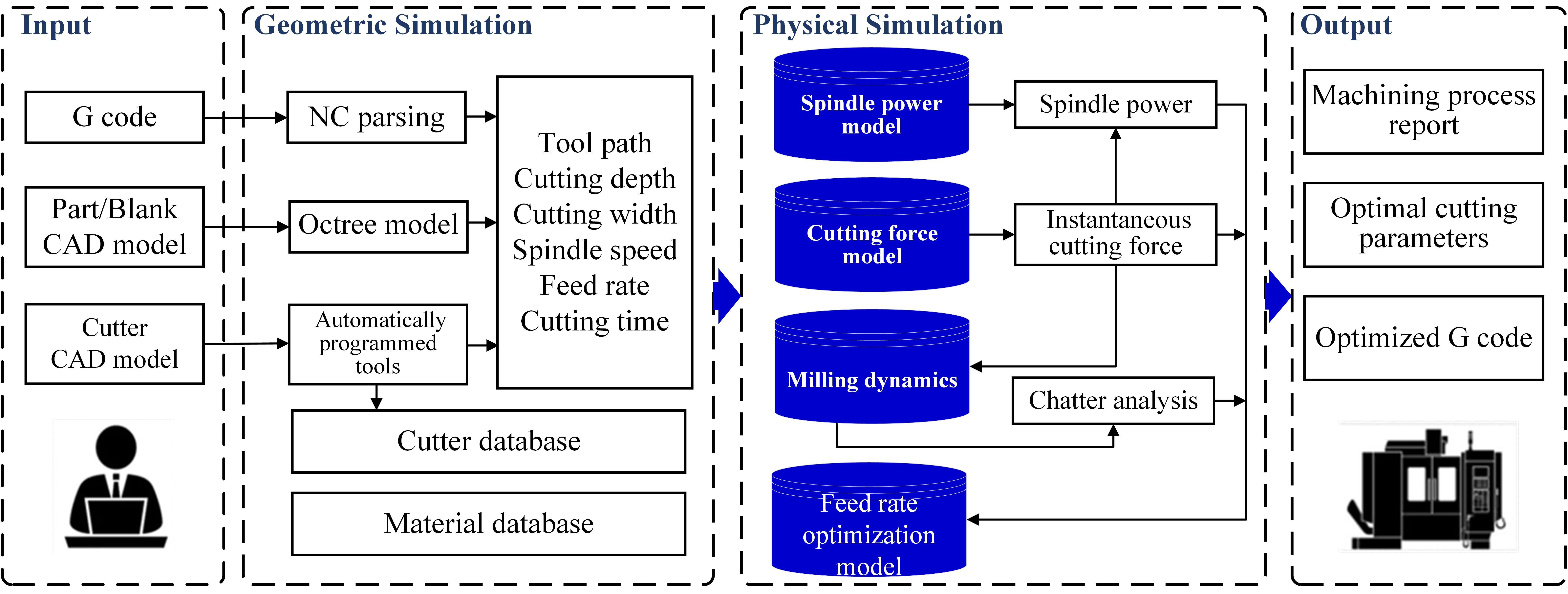

- Virtual Machining System: Chatter Stability Analysis and Feed Rate Optimization

- RA, Supervised by Prof. Ming Chen & Prof. Qinglong An

- Shanghai, China; 09/2019 - 05/2020

- Established a Virtual Machining System specific to thin-wall workpieces, including chatter stability analysis and feed rate optimization, contributing to a 11.2% reduction in average cycle time and 7.4-fold improved surface finish for automotive engine turbine machining

- Established milling dynamics model considering regenerative chatter, and got Stability Lobe Diagram using the zero-order frequency domain solution of which the relative transfer function includes the modal parameters of tool and workpiece

- Obtained the cutter-workpiece engagement area by geometric simulation, utilized the Boolean operation to extract geometrical parameters according to the minimum octants contacting with the cutter, and optimized the feed rate in NC code with Genetic Algorithms to maximize the Material Removal Rate

- More details about Master’s thesis

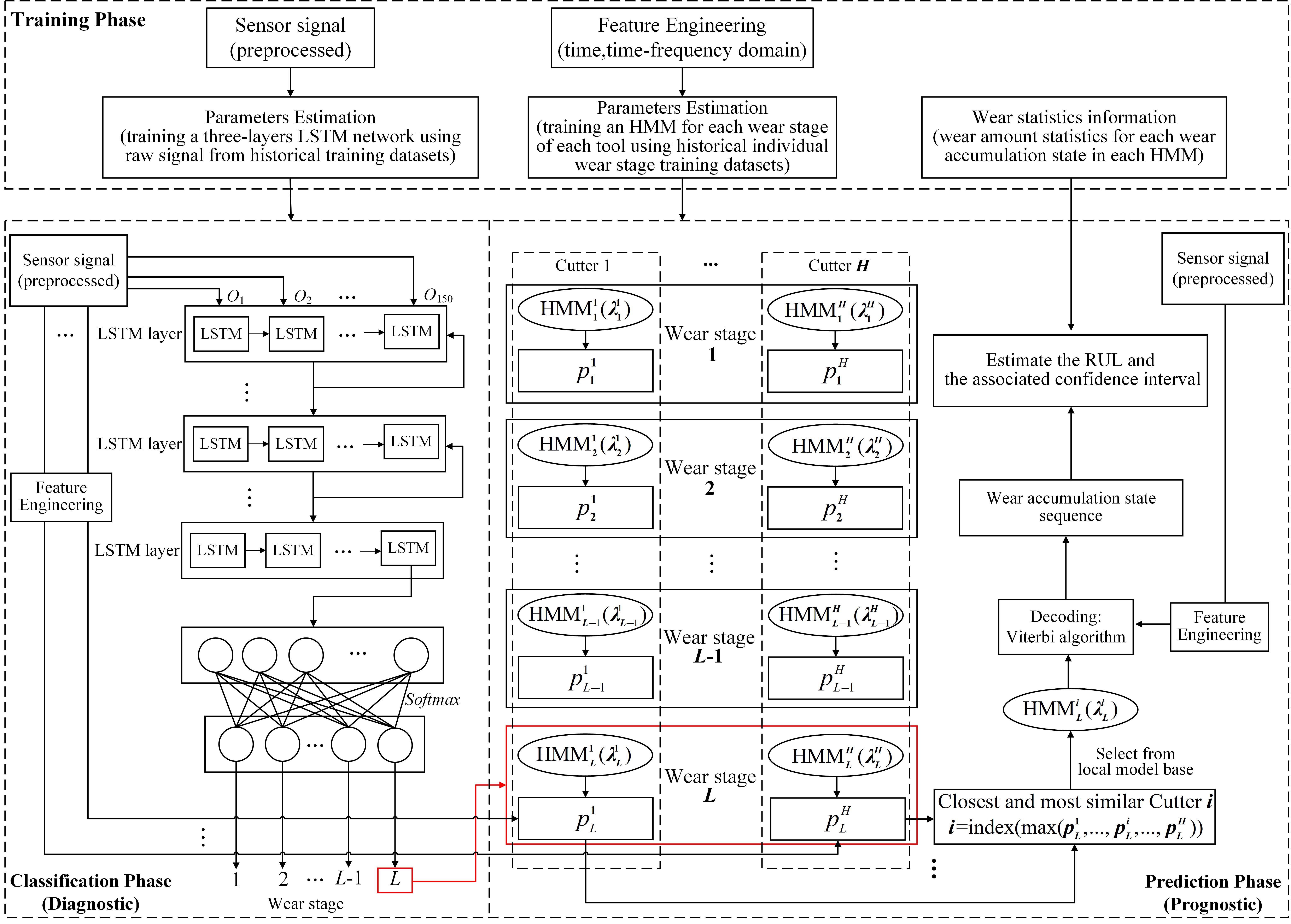

- Tool Condition Monitoring: Diagnostics, Prognostics, and Remaining Useful Life Prediction

- RA, Supervised by Prof. Ming Chen & Prof. Mohamed EL Mansori

- Shanghai, China; 09/2018 - 09/2019

- Developed a hybrid framework based on LSTM and HMM capable of performing TCM during high-speed milling Ti-6Al-4V with diagnostic accuracy reaching up to 0.96 and prognostics MSE decreasing by 93.9%

- Employed the global model (stacked LSTM network) to identify the current tool wear stage, inferred the wear accumulation state sequence using the best-fitted HMM, then calculated the mean wear amount and the associated confidence interval based on the state sequence and wear statistics

- Proposed another integrated model combining CNN with stacked bidirectional and unidirectional LSTMs (SBULSTM) to predict remaining useful life during machining 6063 aluminum alloy smartphone backplate with the three metrics (RMSE/ accuracy/ score) decreased by 77%, increased by 25% and improved by 38% compared with the Random Forest model

- Utilized CNN for local feature extraction and dimension reduction, introduced the SBULSTM network to denoise and encode the temporal information, built multiple fully connected layers on the top of the CNN-SBULSTM network to add nonlinearity, and employed one regression layer to generate the target RUL

- Journal papers: [J1]/[J5]/[J7]; Conference paper: [C2]

- Research on Helical Milling Specialized Tool for CFRP/Titanium alloy

- RA, Supervised by Prof. Jinyang Xu

- Shanghai, China; 09/2017 - 07/2018

- Designed a specialized helical milling tool with distributed multi-point front cutting edge, and evaluated the cutting performances with machined titanium alloy holes burr-free, CFRP holes without delimitation and the service life improved by 50% and 35% compared to the traditional end mill

- Analyzed the chip-splitting results by simulating the undeformed chip formation and each cutting edge’s trajectory, and proceed to iteratively update the structure and geometric parameters of the specialized tool based on the simulation results

- Journal papers:[J4]; Conference paper: [C1]

- Structural Design and Sealing Performance Analysis of Biomimetic Flexible Sealing Ring

- RA, Supervised by Prof. Han Zhang

- Chengdu, China; 09/2016 - 07/2017

- Designed a biomimetic sealing ring inspired by the functional surface of earthworm, which avoids rolling and distortion in dynamic sealing with service life increased by 33.5% and 47.9% compared to O- and rectangular-ring

- Selected the Mooney-Rivlin model to describe the mechanical characteristics of rubber, and established two-dimensional axisymmetric FEM of the biomimetic ring, groove, and slide bar based on the actual setting to analyze Von-Mises stress and contact stress (based on plain strain assumption)

- Research and Development of Low-Shock Non-Explosive Separation Device

- RA, Supervised by Prof. Jian Wu

- Weihai, China; 12/2014 - 07/2015

- Developed a Non-Explosive separation device to connect the launch vehicle and small satellite reliably and release the connection rapidly, and adopted divided nuts to the connect and separate bolt, the four-bar mechanism to control the movement of releasing clamps (divided nuts), eight circumferentially distributed balls to lock the device, and the dual redundant DCmotors to unlock the device

- Generated Solidworks model, drawing and assemblies for the device, verified the bearing capacity by simulation and conducted the pre-stress modal analysis to avoid unlocking mistakenly by external vibration excitation in ANSYS, and simulated the unlocking and separation process by ADAMS

- Manufactured, assembled the parts, and tested the device’s separation time and reliability in vacuum and low temperature environment

Projects

- Multifunctional Medical Nursing Bed

- Supervised by Prof. Ming Chen

- Shanghai, China; 07/2018 - 09/2018

- Modified a commonly used manual nursing bed and added multi functions, such as anti-slip, easy dismantling and hemorrhoids prevention, promoted the blood circulation of the patient’s legs and reduce the muscle atrophy caused

- Analyzed the kinematics of the drive mechanism to make sure that the platform can cover the testing angle range and position accurately at a specific angle

- More details

- End-actuator for Oil Tank Insulation-layer Surface Trimming and Its Process Planning

- Supervised by Prof. Ming Chen

- Shanghai, China; 09/2017 - 03/2018

- Designed a flexible end-actuator for insulation-layer surface trimming, including functions of distance measurement and radial feed adjustment, with the ability to control the thickness deviation between ±1mm for the diameter ranging from 2250 to 3350 mm

- Proposed a collaboration method based on Support Vector Machine Regression to minimize the distance measurement error and used radial basis neural networks to compensate for the errors in different distance intervals

- Planned the processing technology referring to bar turning, in which the eddy current displacement sensor determines the radial depth of cut, and the robot arm carries the end-actuator back and forth when the tank rotates around the axis

- More details

- Angle Measuring Platform for Fully Articulated Main Hub of Helicopter Rotor Systems

- Supervised by Prof. Jian Wu

- Weihai, China; 05/2015 - 09/2016

- Developed a platform to measure three angle parameters range for fully articulated main hub, which allows each blade to lead/lag (move back and forth in-plane), flap (move up and down about an inboard-mounted hinge), and feather (rotate about the pitch axis) independent of the other blades, implemented control system including user interface and query function, and reduced the whole measuring process from 3 hours to 40 minutes.

- Analyzed the statics and kinematics of the drive mechanism using ANSYS and MATLAB, solved the stress of the main components and the coupling relationship between three angles, which iteratively update the design parameters to guarantee the structural strength of the platform, cover the required angle ranges and position accurately at specific angles

- More details